Custom Diamond Reamers by TAKEZAWA-SEIKI

Takezawa Seiki specializes in designing custom diamond reamers that are tailored to your company’s unique needs. We take into account your workpiece, replacement, and required accuracy to create the ideal tool and process for your business. Our diamond reamers are shaped according to your specific environment, taking into consideration factors such as replaceability, workpiece shape and material, required accuracy, and tool life.

Takezawa Seiki, a professional group of one-pass honing processing, has a track record of manufacturing diamond reamers suitable for various conditions. After fully understanding and sharing the customer’s processing environment, conditions, and concerns, we propose the optimal diamond reamer. If you are thinking about improving the productivity of your honing processing line, please consult with Takezawa Seiki.

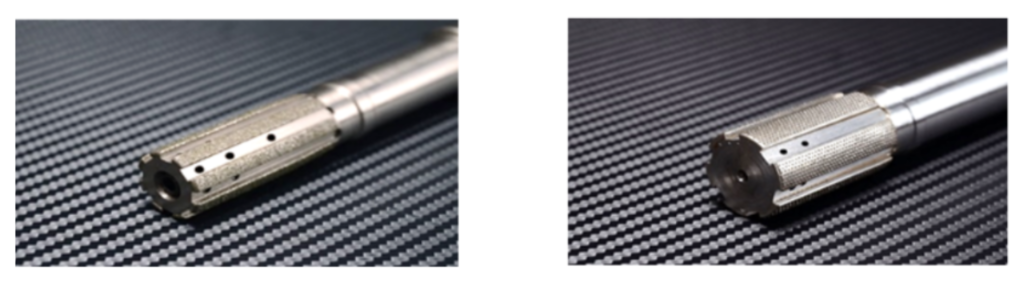

Customer-specific diamond reamer design examples

Takezawa Seiki provides different types of custom diamond reamers based on your specific needs and applications.

Expansion type

Emphasis on tool life 【 Model: DLS】

When the abrasive grains on the reamer wear out, the diameter of the reamer becomes smaller. However, it can be restored to its original size by expanding it. This means that the reamer can last 2-3 times longer than rigid reamers. Depending on the material, cost, and other factors, the reamer can usually last about 10,000 holes, and in the best case, up to 30,000 holes.

Non-Expansion type

Emphasis on tool rigidity and high precision 【 Model: SL etc. 】

Because it is made from one solid material, it is very sturdy. This also means that highly precise reamers can be made without having to adjust the diameter separately, allowing for high-precision machining.

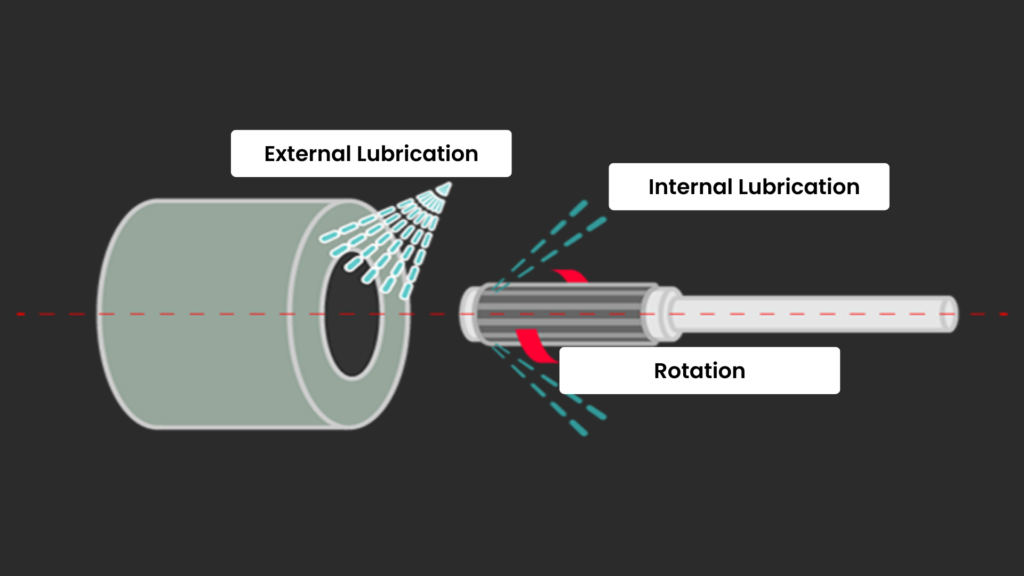

Horizontal machining centers

This tool can be used on many types of machine tools. Even on horizontal machining centers, it can achieve high-precision honing by adjusting for runout and using internal coolant to prevent chips from building up.

1. Sideways orientation affects tool runout. Countermeasures such as runout adjustment holders are used.

2. Sideways orientation makes it hard for cutting oil to enter. A countermeasure is to add internal lubrication through an oil hole.

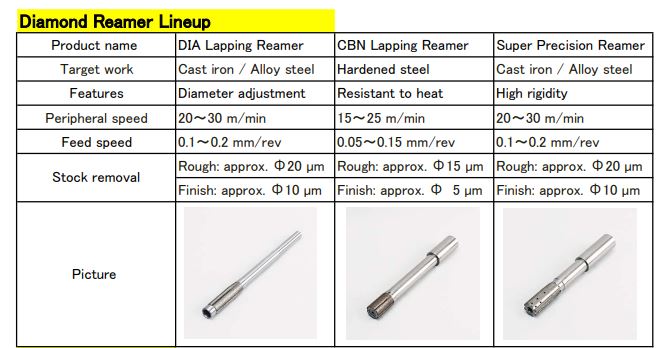

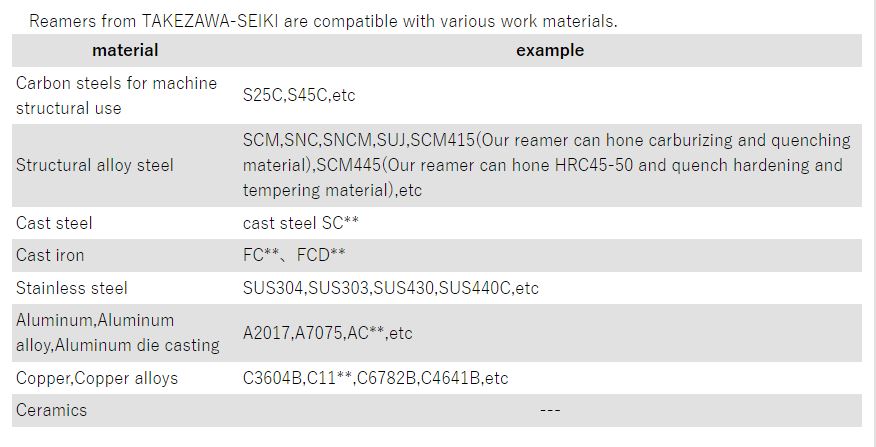

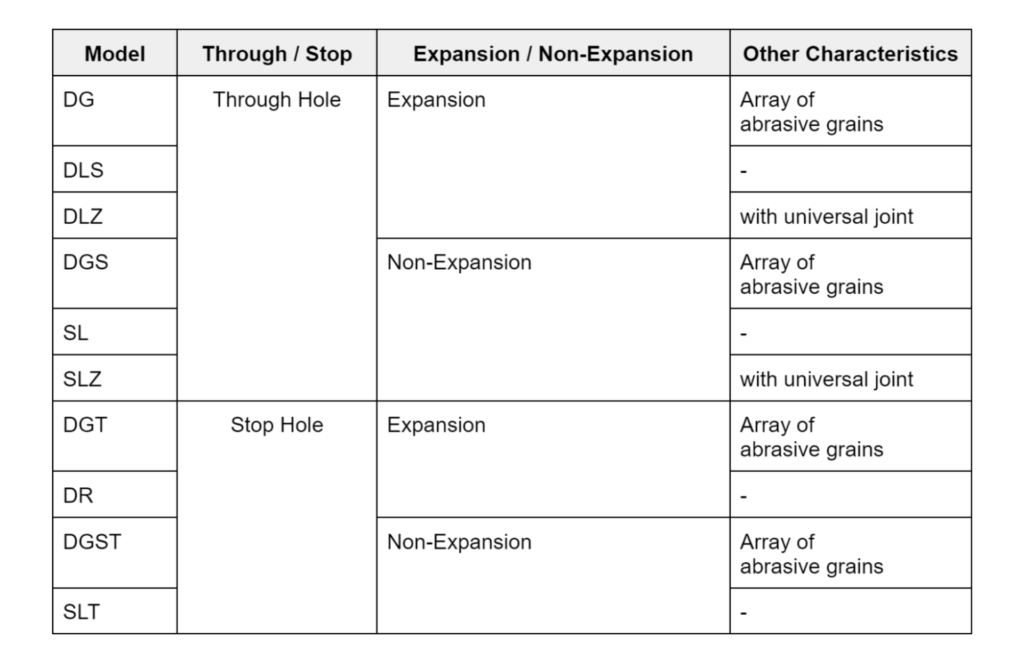

We can provide detailed proposals based on the workpiece material, hardness, and replacement requirements. You can refer to the model list below for more information.

Wide Range Of Reamers

Model List

Reference Web: http://www.takezawa-seiki.co.jp/reamer/reamer.html

Optimize Honing with Takezawa Seiki’s One-Pass Technology

Takezawa Seiki’s one-pass honing process can take your production site to the next level. Compared to traditional honing wheel machining, it achieves both high speed and low introduction cost (*1), allowing the use of general-purpose machine tools as-is. This process is highly regarded by customers across various fields. Takezawa Seiki’s one-pass honing improves the low productivity of the honing process at a low cost. If you are interested in improving your honing process, please contact Takezawa Seiki. We also offer a dedicated processing machine (honing machine) with higher performance.

Who is TAKEZAWA-SEIKI?

Takezawa Seiki is a specialized group with over 40 years of experience in honing processing. We design and develop diamond reamers, holders, special processing machines, and a series of equipment related to honing. One of Takezawa Seiki’s unique features is our ability to solve problems from multiple perspectives throughout the honing process.

We aim to understand our customers’ problems and concerns by visiting their production sites, and then make proposals based on this understanding. Our goal is to solve problems in the way that best suits our customers’ needs. If you have any inquiries related to hole processing, please do not hesitate to contact Takezawa Seiki.

What is a Diamond Reamer?

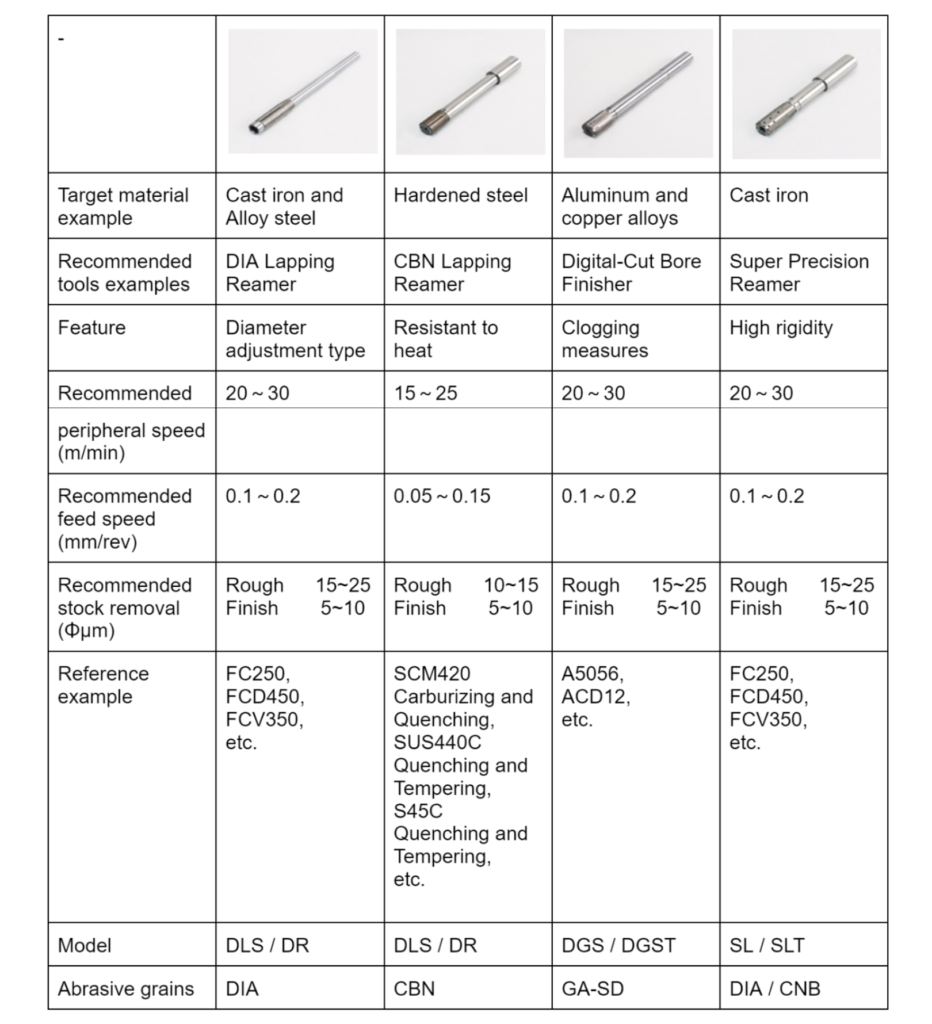

This is an electrodeposited reamer that utilizes diamond (DIA) or CBN abrasive grains. By sharpening the workpiece with countless electrodeposited abrasive grains, the cutting force per abrasive grain can be reduced, leading to extremely high machining accuracy that is maintained consistently.

Moreover, the DIA/CBN material used in the abrasive grains has a very high material removal rate, making it possible to achieve high-precision polishing with a one-pass honing process.

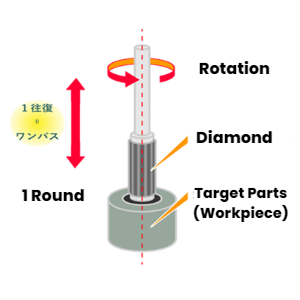

What is One-pass Honing?

Takezawa Seiki confidently recommends the revolutionary grinding method of “One-pass honing”, which uses a diamond reamer to achieve ultra-high precision in a single pass for the inner diameter of a workpiece.

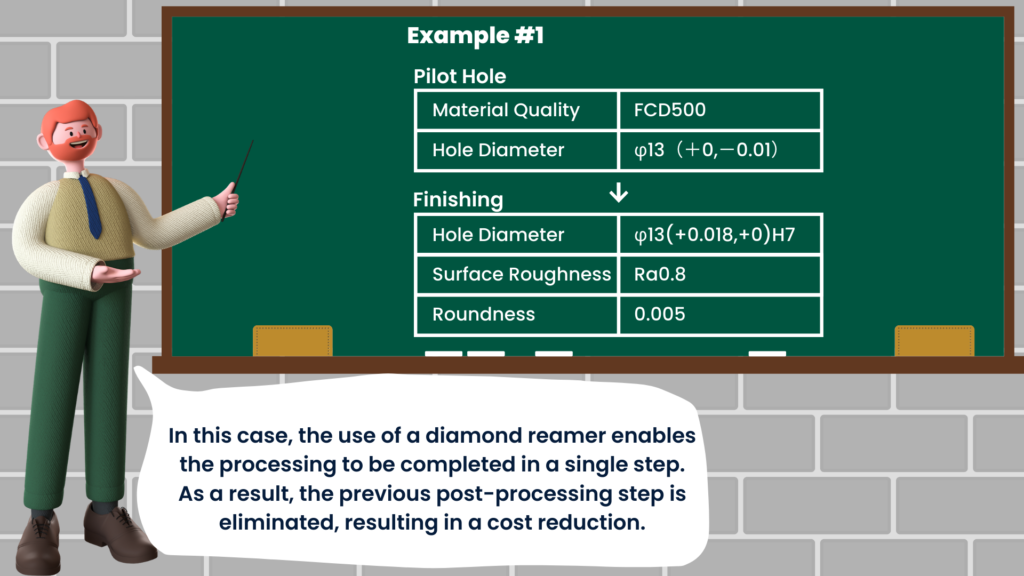

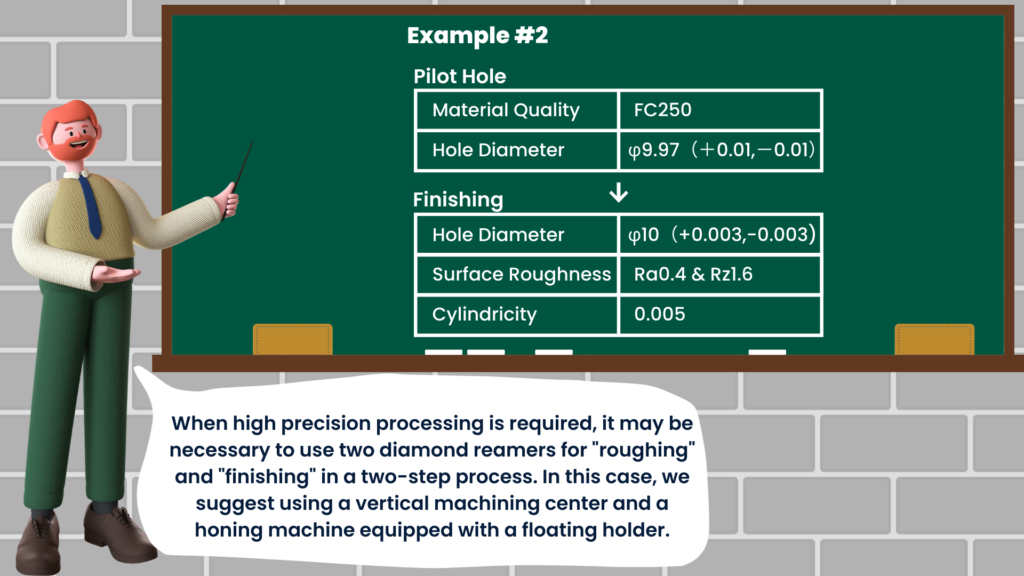

Example of proposal for One-pass Honing process design

* The actual process may differ depending on the material and other processing conditions.

3 reasons why One-pass Honing is valued

The reason for this is that “one-pass honing” has the potential to achieve efficient machining that is not possible with conventional honing wheels, and eliminates the need for additional equipment investment. By using a diamond reamer with a general-purpose machining center, high-speed and high-precision honing can be achieved without the need for new capital investments.

This demonstrates the possibility of increasing productivity on your production line and achieving cost savings at an unprecedented level.

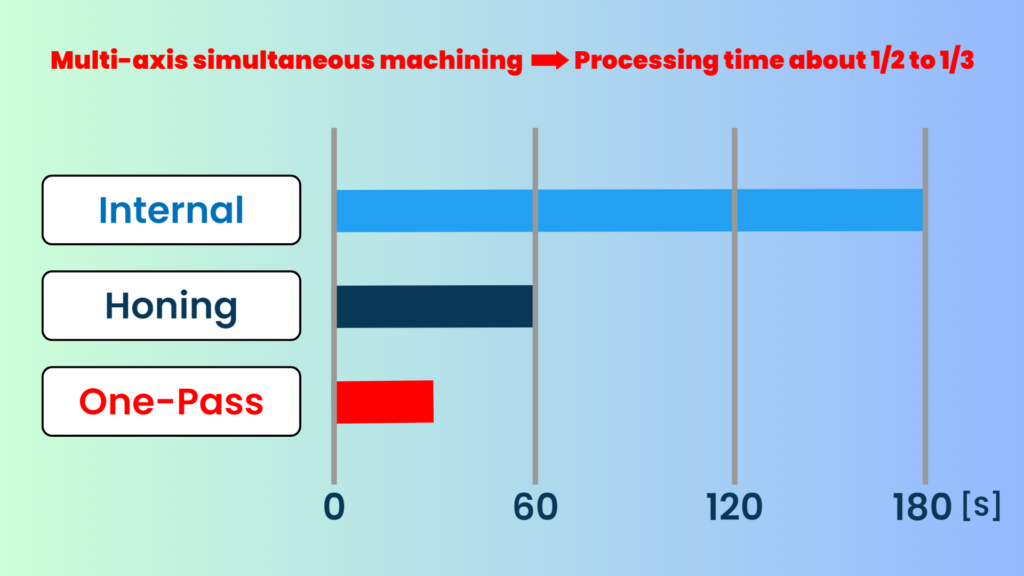

Reason 1: High productivity

Efficient process dispersion – productivity increased by more than 200%

One-pass honing completes honing in a single pass, which can reduce machining time even when large amounts of material need to be removed and the process is divided into multiple steps. In some cases, our machines equipped with multi-axis mechanisms have increased productivity by over 1%. By dispersing the process, the cycle time can be shortened, and as a result, the hourly production output can be increased, leading to improved productivity.

Takezawa Seiki’s one-pass honing has the potential to significantly improve the efficiency of your production line.

*Actual machining time may vary depending on the specifications and conditions.

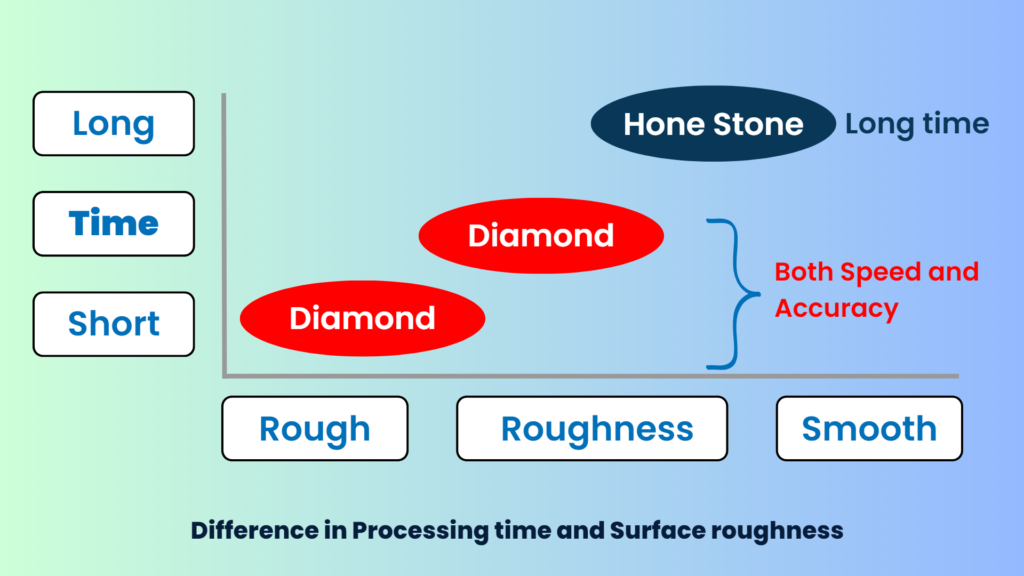

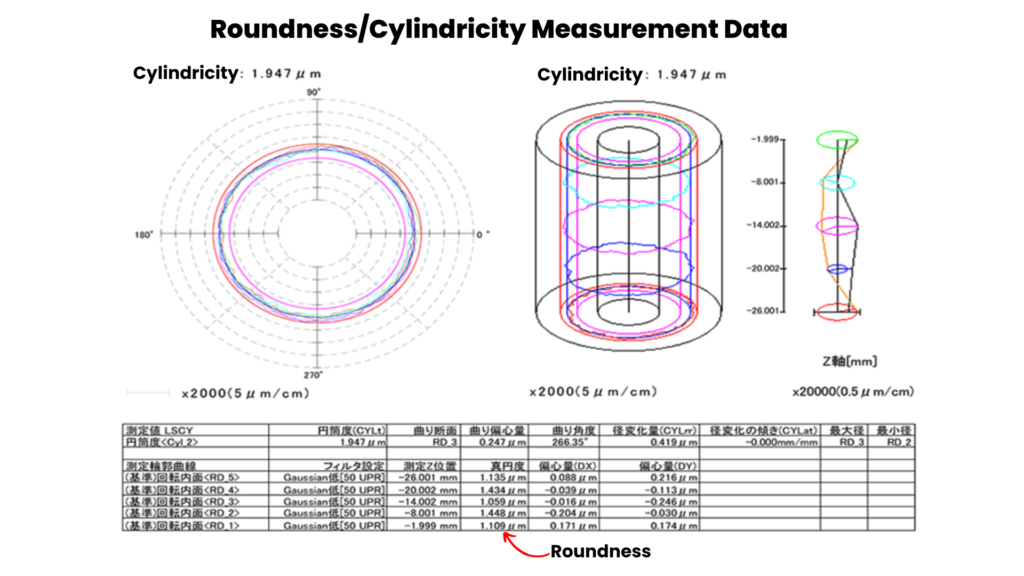

Reason 2: Super high precision

Fast and cheap, but super finish approaching honing whetstones.

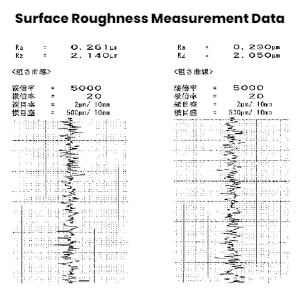

Takezawa Seiki’s diamond reamer can achieve a surface roughness of around 0.1 micrometers (μm)*, which is comparable to honing wheel machining. If you’re currently using honing wheels, consulting with Takezawa Seiki might help you improve your production efficiency and reduce costs significantly. We always put our customers first and carefully analyze how to streamline their honing process. Don’t hesitate to contact us.

*Surface roughness may vary depending on the processing conditions.

This is information based on testing and processing done in-house. The accuracy of the machining and the lifespan of the tool can vary based on factors such as the type of workpiece and the conditions of the machining process.

Reference Web: http://www.takezawa-seiki.co.jp/reamer/index.html

Takezawa Diamond Reamers

Takezawa Diamond Reamers range in size from 3/32″ (2.5mm) to 6″ (150mm). They are time-proven to deliver superior accuracy with extended tool life in demanding low-tolerance honing applications in cast iron, hardened steel, alloy steels, aluminum, bronze, brass & ceramics.

Three Diamond Reamer Models/ Reference Examples

DLS Model

1. Standard type for through holes.

2. Adjustable type.

3. The abrasive grain is DIA or CBN electrodeposition

DR Model

1. Standard type for blind holes.

2. Adjustable type

3. The abrasive grain is DIA or CBN electrodeposition.

SL Model

1. Standard type for through holes.

2. Nonadjustable type.

3. The abrasive grain is DIA or CBN electrodeposition.