Takezawa Seiki’s one-pass honing process can take your production site to the next level. Compared to traditional honing wheel machining, it achieves both high speed and low introduction cost (*1), allowing the use of general-purpose machine tools as-is. This process is highly regarded by customers across various fields. Takezawa Seiki’s one-pass honing improves the low productivity of the honing process at a low cost. If you are interested in improving your honing process, please contact Takezawa Seiki. We also offer a dedicated processing machine (honing machine) with higher performance.

Who is TAKEZAWA-SEIKI?

Takezawa Seiki is a specialized group with over 40 years of experience in honing processing. We design and develop diamond reamers, holders, special processing machines, and a series of equipment related to honing. One of Takezawa Seiki’s unique features is our ability to solve problems from multiple perspectives throughout the honing process.

We aim to understand our customers’ problems and concerns by visiting their production sites, and then make proposals based on this understanding. Our goal is to solve problems in the way that best suits our customers’ needs. If you have any inquiries related to hole processing, please do not hesitate to contact Takezawa Seiki.

What is a Diamond Reamer?

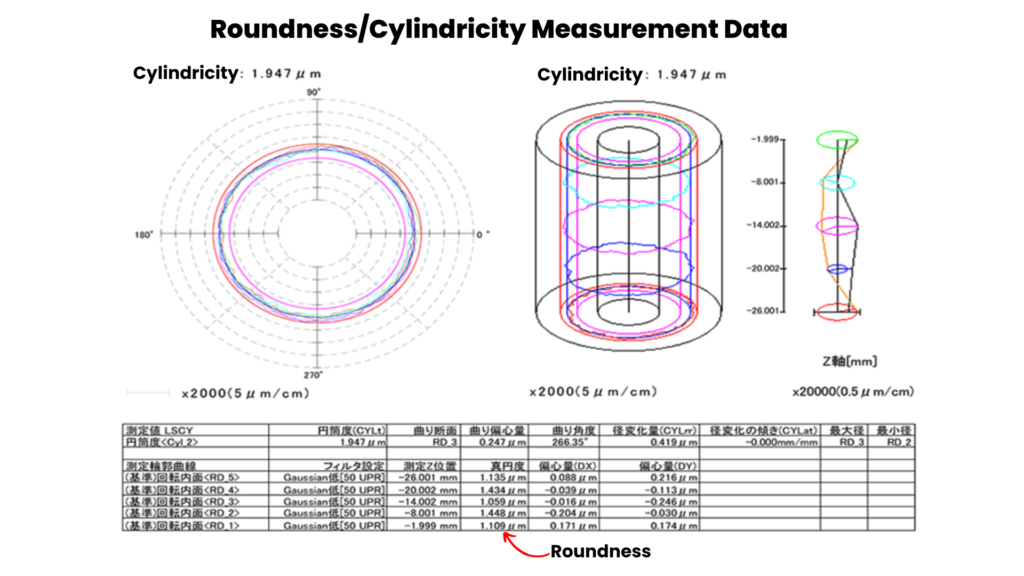

This is an electrodeposited reamer that utilizes diamond (DIA) or CBN abrasive grains. By sharpening the workpiece with countless electrodeposited abrasive grains, the cutting force per abrasive grain can be reduced, leading to extremely high machining accuracy that is maintained consistently.

Moreover, the DIA/CBN material used in the abrasive grains has a very high material removal rate, making it possible to achieve high-precision polishing with a one-pass honing process.

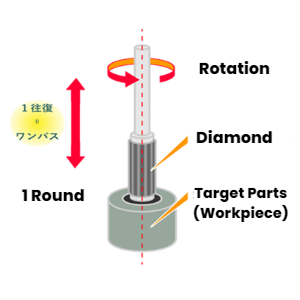

What is One-pass Honing?

Takezawa Seiki confidently recommends the revolutionary grinding method of “One-pass honing”, which uses a diamond reamer to achieve ultra-high precision in a single pass for the inner diameter of a workpiece.

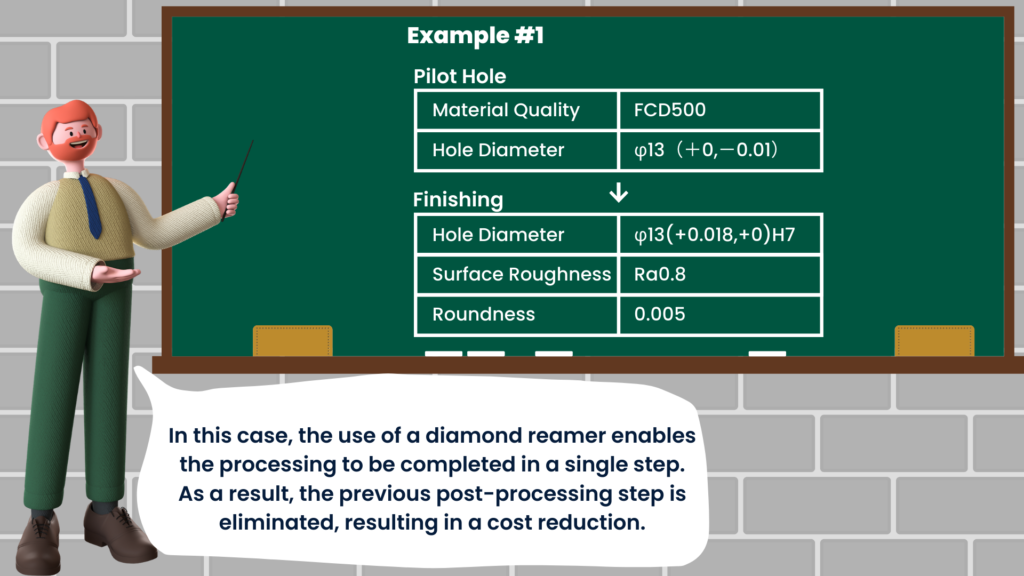

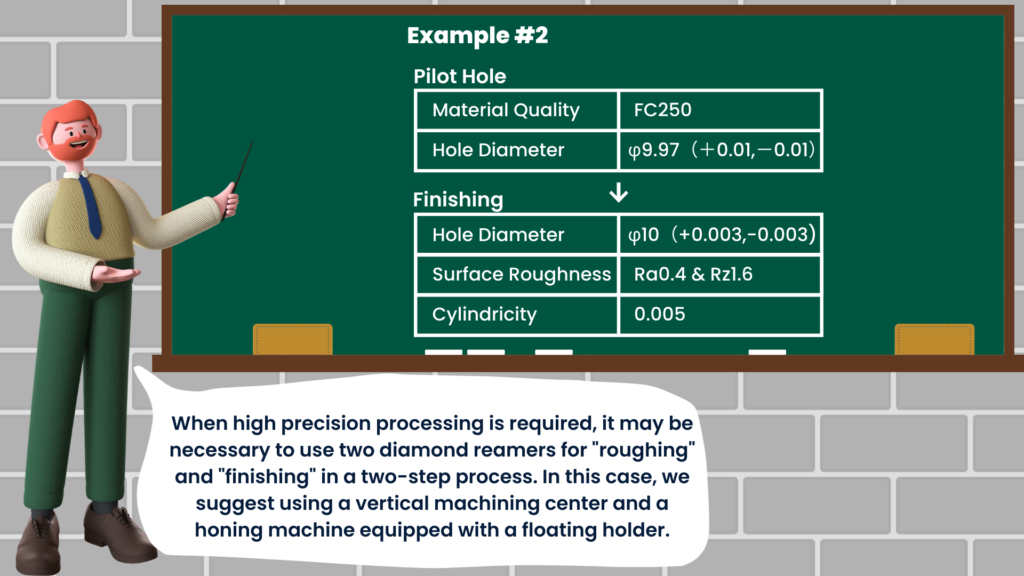

Example of proposal for One-pass Honing process design

* The actual process may differ depending on the material and other processing conditions.

3 reasons why One-pass Honing is valued

The reason for this is that “one-pass honing” has the potential to achieve efficient machining that is not possible with conventional honing wheels, and eliminates the need for additional equipment investment. By using a diamond reamer with a general-purpose machining center, high-speed and high-precision honing can be achieved without the need for new capital investments.

This demonstrates the possibility of increasing productivity on your production line and achieving cost savings at an unprecedented level.

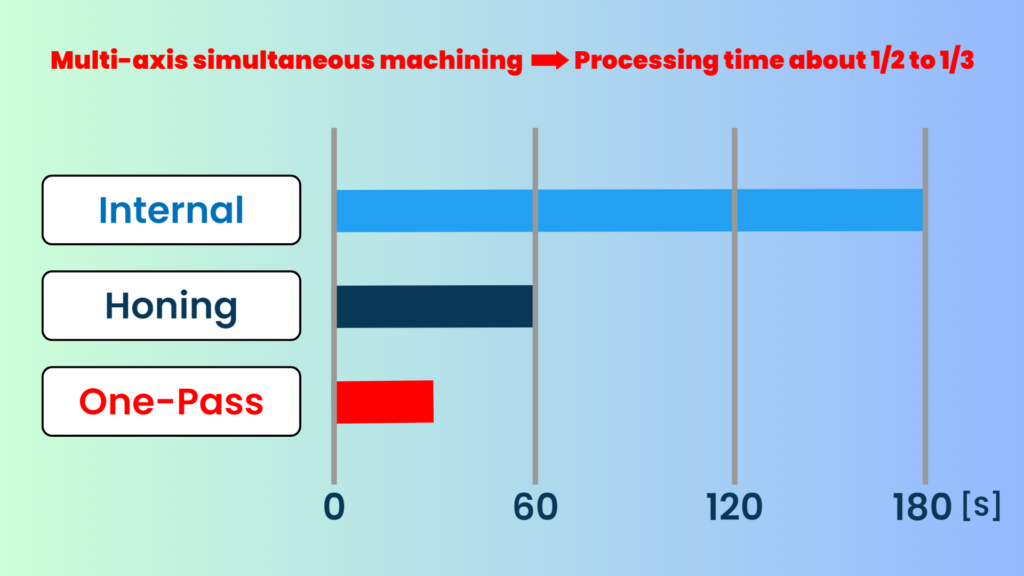

Reason 1: High productivity

Efficient process dispersion – productivity increased by more than 200%

One-pass honing completes honing in a single pass, which can reduce machining time even when large amounts of material need to be removed and the process is divided into multiple steps. In some cases, our machines equipped with multi-axis mechanisms have increased productivity by over 1%. By dispersing the process, the cycle time can be shortened, and as a result, the hourly production output can be increased, leading to improved productivity.

Takezawa Seiki’s one-pass honing has the potential to significantly improve the efficiency of your production line.

*Actual machining time may vary depending on the specifications and conditions.

Reason 2: Super high precision

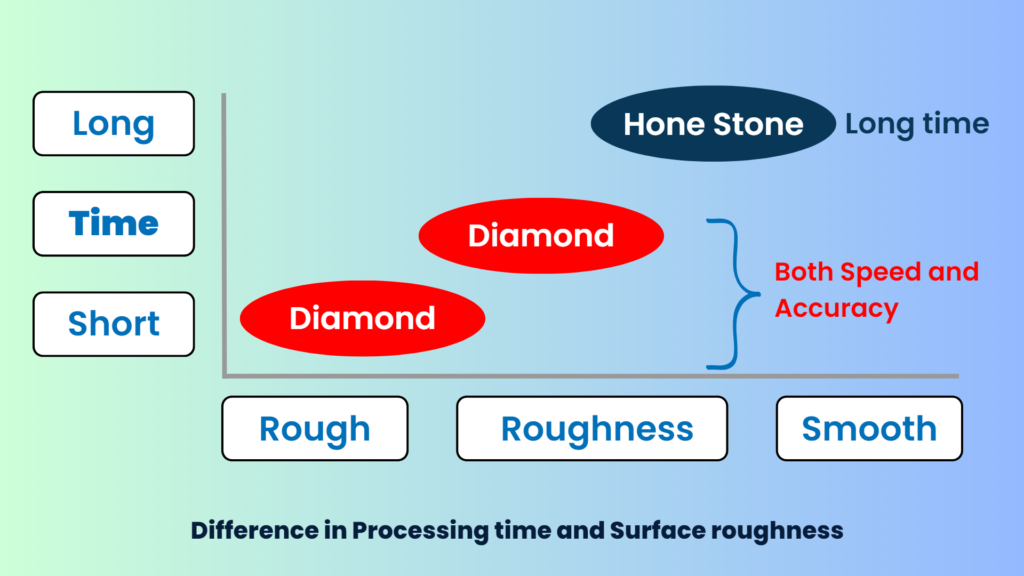

Fast and cheap, but super finish approaching honing whetstones.

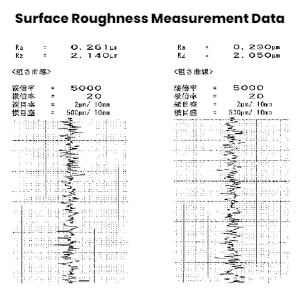

Takezawa Seiki’s diamond reamer can achieve a surface roughness of around 0.1 micrometers (μm)*, which is comparable to honing wheel machining. If you’re currently using honing wheels, consulting with Takezawa Seiki might help you improve your production efficiency and reduce costs significantly. We always put our customers first and carefully analyze how to streamline their honing process. Don’t hesitate to contact us.

*Surface roughness may vary depending on the processing conditions.

This is information based on testing and processing done in-house. The accuracy of the machining and the lifespan of the tool can vary based on factors such as the type of workpiece and the conditions of the machining process.

Reference Web: http://www.takezawa-seiki.co.jp/reamer/index.html