Takezawa Seiki specializes in designing custom diamond reamers that are tailored to your company’s unique needs. We take into account your workpiece, replacement, and required accuracy to create the ideal tool and process for your business. Our diamond reamers are shaped according to your specific environment, taking into consideration factors such as replaceability, workpiece shape and material, required accuracy, and tool life.

Takezawa Seiki, a professional group of one-pass honing processing, has a track record of manufacturing diamond reamers suitable for various conditions. After fully understanding and sharing the customer’s processing environment, conditions, and concerns, we propose the optimal diamond reamer. If you are thinking about improving the productivity of your honing processing line, please consult with Takezawa Seiki.

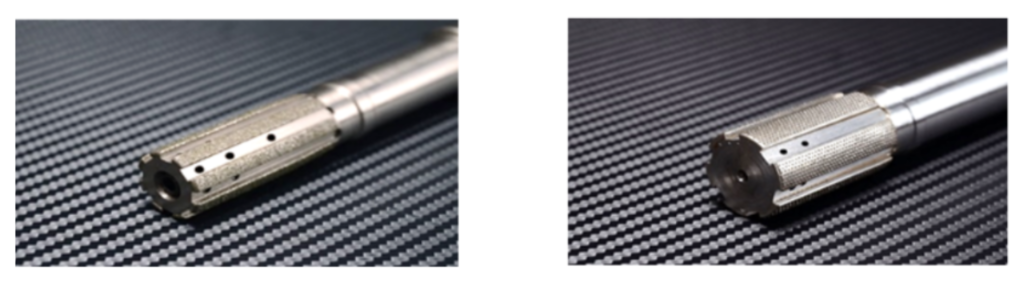

Customer-specific diamond reamer design examples

Takezawa Seiki provides different types of custom diamond reamers based on your specific needs and applications.

Expansion type

Emphasis on tool life 【 Model: DLS】

When the abrasive grains on the reamer wear out, the diameter of the reamer becomes smaller. However, it can be restored to its original size by expanding it. This means that the reamer can last 2-3 times longer than rigid reamers. Depending on the material, cost, and other factors, the reamer can usually last about 10,000 holes, and in the best case, up to 30,000 holes.

Non-Expansion type

Emphasis on tool rigidity and high precision 【 Model: SL etc. 】

Because it is made from one solid material, it is very sturdy. This also means that highly precise reamers can be made without having to adjust the diameter separately, allowing for high-precision machining.

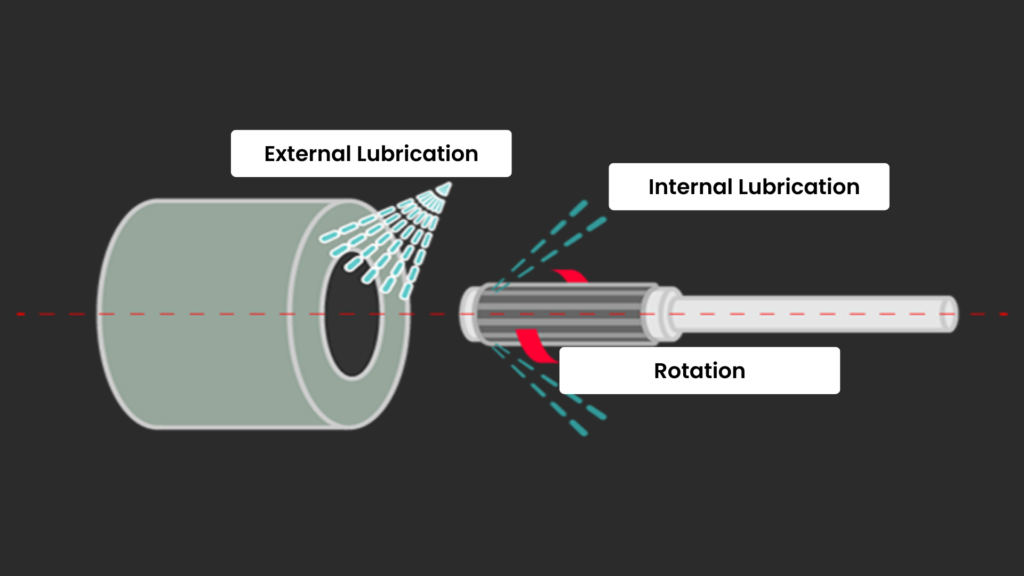

Horizontal machining centers

This tool can be used on many types of machine tools. Even on horizontal machining centers, it can achieve high-precision honing by adjusting for runout and using internal coolant to prevent chips from building up.

1. Sideways orientation affects tool runout. Countermeasures such as runout adjustment holders are used.

2. Sideways orientation makes it hard for cutting oil to enter. A countermeasure is to add internal lubrication through an oil hole.

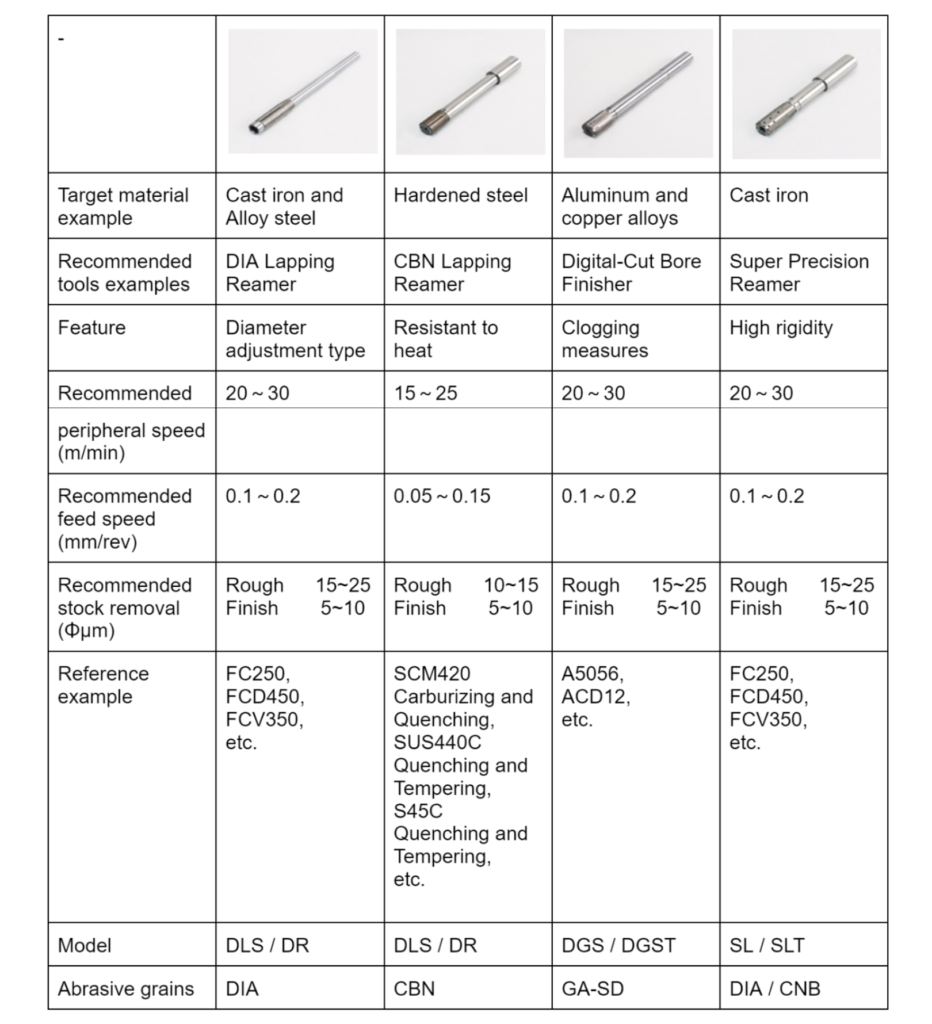

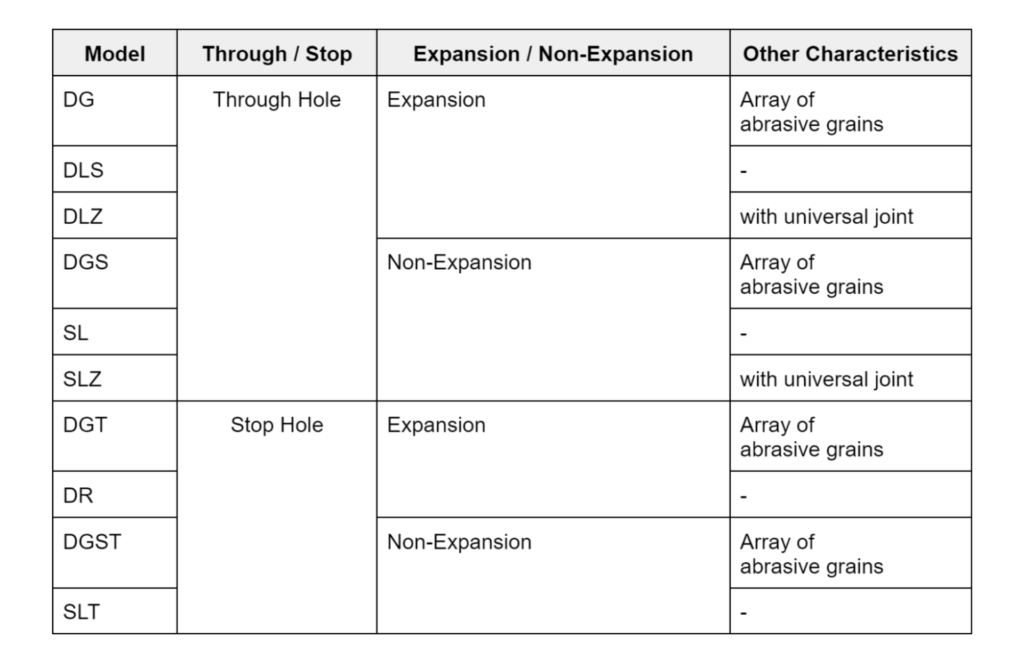

We can provide detailed proposals based on the workpiece material, hardness, and replacement requirements. You can refer to the model list below for more information.

Wide Range Of Reamers

Model List

Reference Web: http://www.takezawa-seiki.co.jp/reamer/reamer.html