To overcome challenges such as tool damage and galling due to chips, as well as the degradation of machining accuracy caused by insufficient machine tool rigidity during reaming machining, honing reamers has become increasingly important. Takezawa Seiki has developed advanced honing reamer machine tools that allow for higher levels of cylindrical grinding, ultimately maximizing reamer performance. Our honing reamer products are designed to provide benefits to a diverse range of customers.

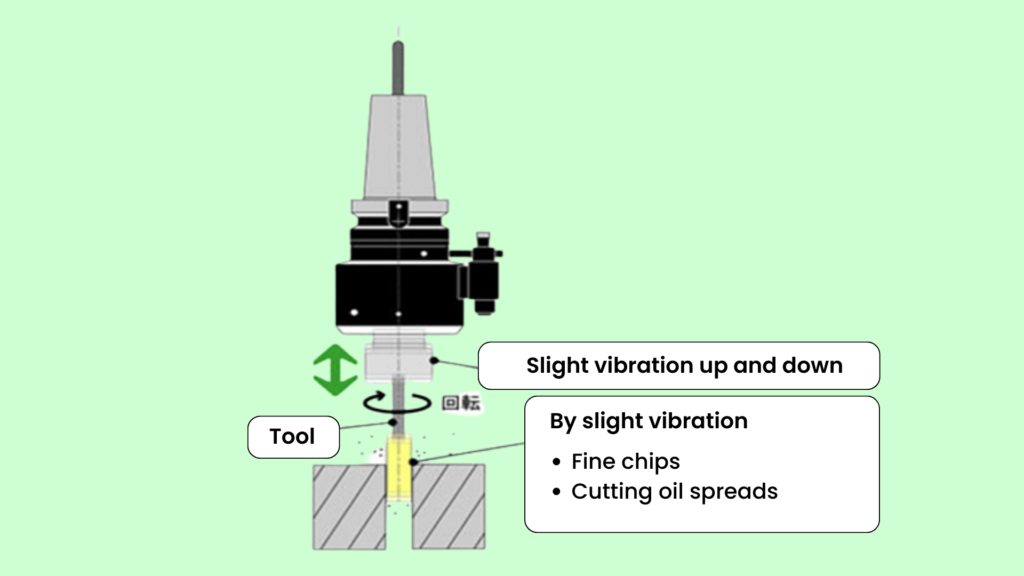

Takezawa Seiki’s honing reamer machine is equipped with an excitation mechanism that significantly enhances machining accuracy, resulting in superior precision and surface finish.

Vibrating the reamer enables the chips to be cut into smaller pieces, which are then automatically discharged. This process leads to a significant improvement in surface roughness and tool life, and enables ultra-high-precision honing.

Our innovative technology prevents the chips from damaging the tool and prevents the tool from galling by utilizing the vibration mechanism.

Model: THL-05 (Micron Boy)

Demonstrating our strength in small-lot, high-mix production

In small-lot, high-mix production, frequent setup changes can lead to a decrease in productivity. Conventional automated reaming machines require changing settings and other adjustments each time the workpiece changes, making them unsuitable for such production scenarios.

To address this issue, THL-05 adopts a unique semi-automation method that automates only processes related to machining accuracy, while allowing flexible human intervention to accommodate variations in workpiece shapes.

By combining the precision of automation with the adaptability of human workers, THL-05 achieves high productivity in small-lot, high-mix production.

Ease of use that can be quickly learned even if you have no machining experience.

The THL-05 is designed for ease of use and does not require skilled workers. All parts related to machining accuracy are performed automatically. Once you have adjusted the knob according to the shape of the workpiece, you can start machining by simply setting the processing length and rotation speed. There is no need to acquire specialized skills like those required for operating a drilling machine, nor do you need specialized knowledge or complicated commands like those needed for an NC machine.

Less space-saving than B1 paper

The installation area is the world’s smallest class for a reaming machine, with a width of 700 mm and a depth of 950 mm.

This indicates that it can be installed in a smaller space than B1 paper.

Processing accuracy of 0.5s with one-pass honing

Combining one-pass honing with Takezawa Seiki’s honing reamer enables ultra-high-precision machining up to 0.5μm. Additionally, the spindle rotation speed can be set up to 4000 rpm, providing sufficient peripheral speed to maintain machining accuracy, even for small-diameter machining of about φ2.5.

Low implementation cost

The THL-05 is optimized for processing a wide variety of small quantity products. It is easy to use, highly accurate, and space-saving while equipped with sufficient functions. Additionally, it offers strong customer support even at the introduction cost.

We have achieved a price point that is about half that of the conventional model.

Reference web: http://www.takezawa-seiki.co.jp/machine/index.html

Promotion movie of THL05 and Diamond reamer.

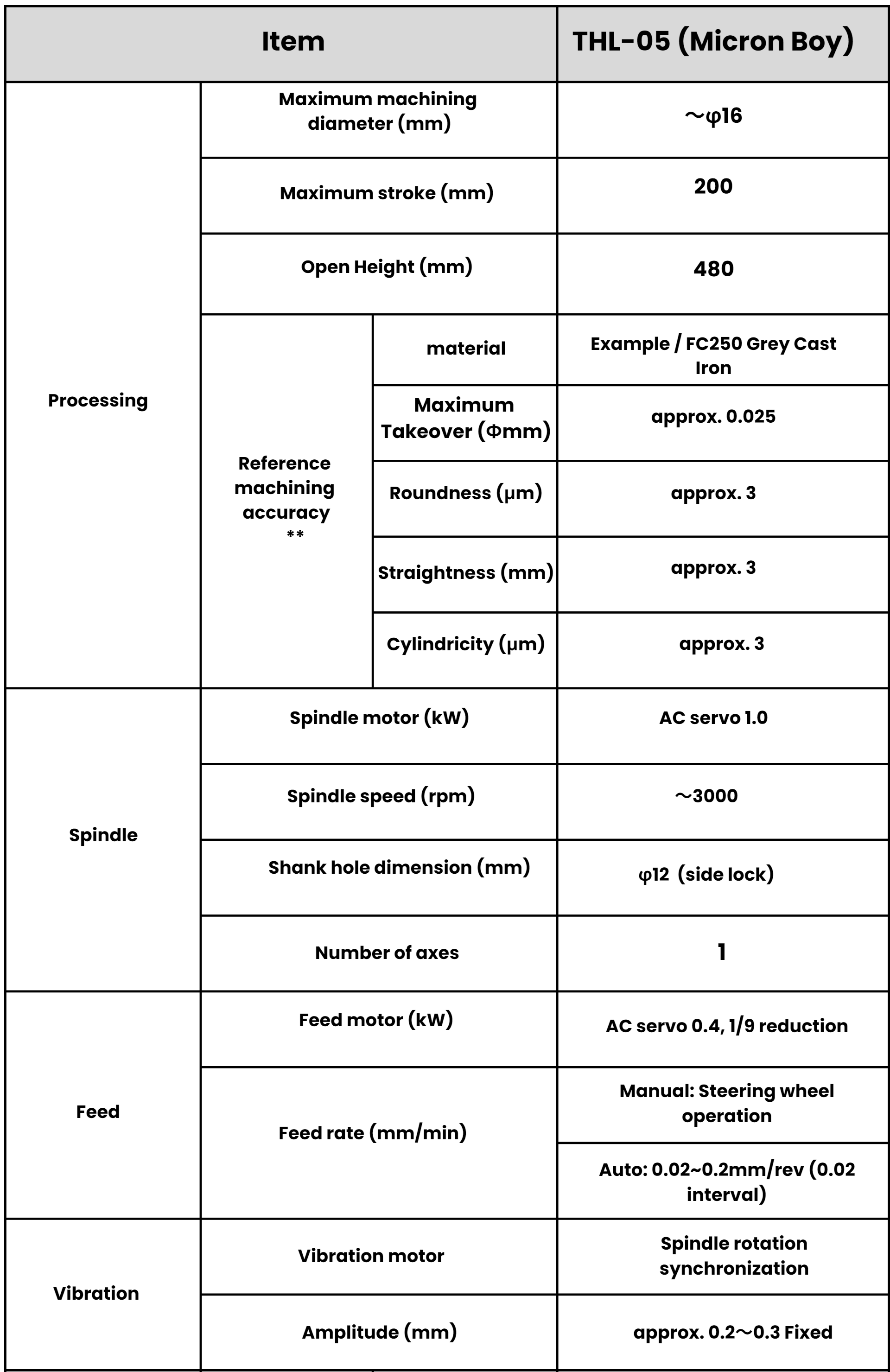

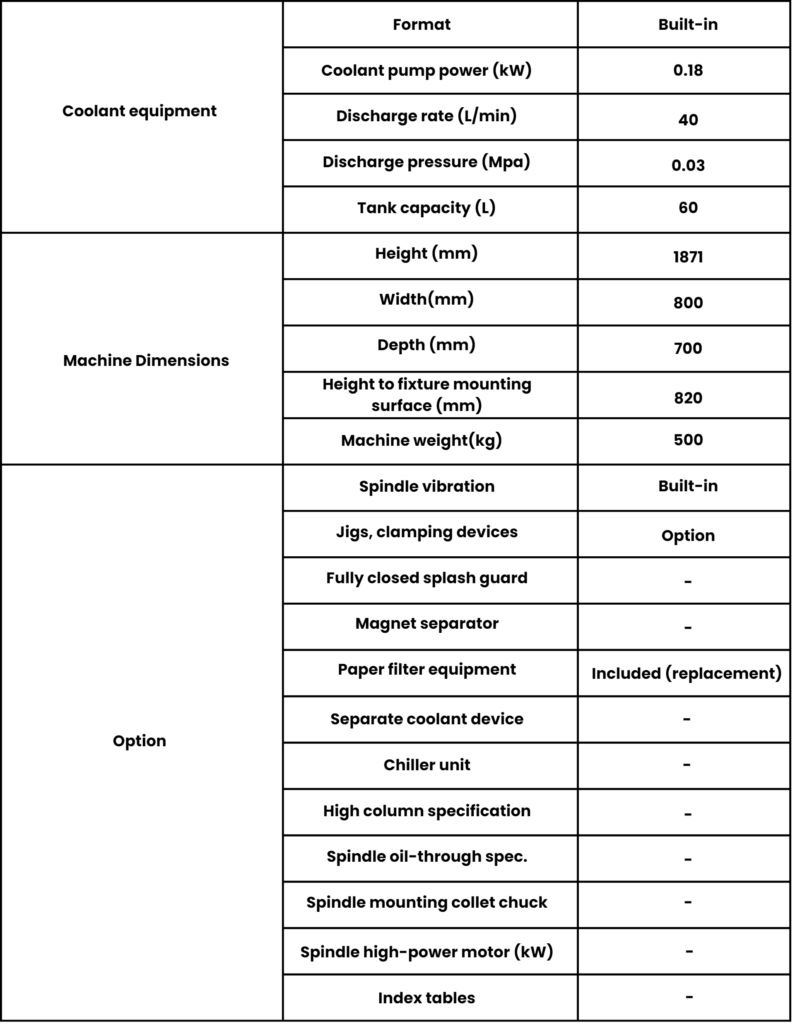

Main Specification of THL-05 *

*The machine specifications may vary depending on design updates, production circumstances, and other factors.

*Actual machining accuracy and tool life may vary depending on workpiece specifications, pre-processing accuracy, machining conditions, measurement methods, and other factors