Follows even the smallest offsets.

In honing, where very high precision is required, even small deviations between the center of the tool and the center of the pilot hole can have a significant impact on machining accuracy, quality, and tool life.

Takezawa Seiki’s floating honing holder, designed specifically for one-pass honing, addresses these issues and improves machining accuracy, reduces variation in quality, and extends tool life.

Floating honing holder improves machining accuracy.

・Even if there is an offset between the center of the tool and the center of the pilot hole, the accuracy does not deteriorate, such as the enlargement of the hole diameter.

・As no excessive force is applied to the tool, it is less likely to wear or break.

・Positioning errors in workpieces and tools do not affect machining accuracy; thus, the quality remains constant.

Floating honing holders can reduce costs.

・With a small investment in the holder, higher levels of processing can be achieved than before.

・Production efficiency can be improved by reducing the number of setup hours required when changing tools.

・Lead time can be reduced through high-speed machining.

・Consistency in quality can be maintained, which leads to less rework and reduced loss due to defective products.

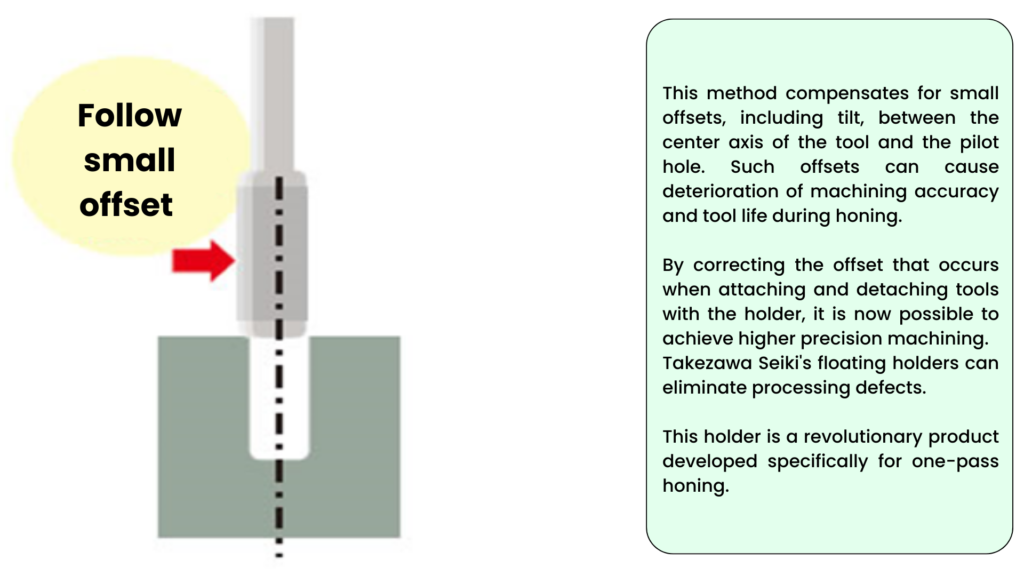

Method of minimizing or correcting the offset (core misalignment) between the pilot hole and the tool center axis.

This method compensates for small offsets, including tilt, between the center axis of the tool and the pilot hole. Such offsets can cause deterioration of machining accuracy and tool life during honing.

By correcting the offset that occurs when attaching and detaching tools with the holder, it is now possible to achieve higher precision machining.

Takezawa Seiki’s floating holders can eliminate processing defects.

This holder is a revolutionary product developed specifically for one-pass honing.

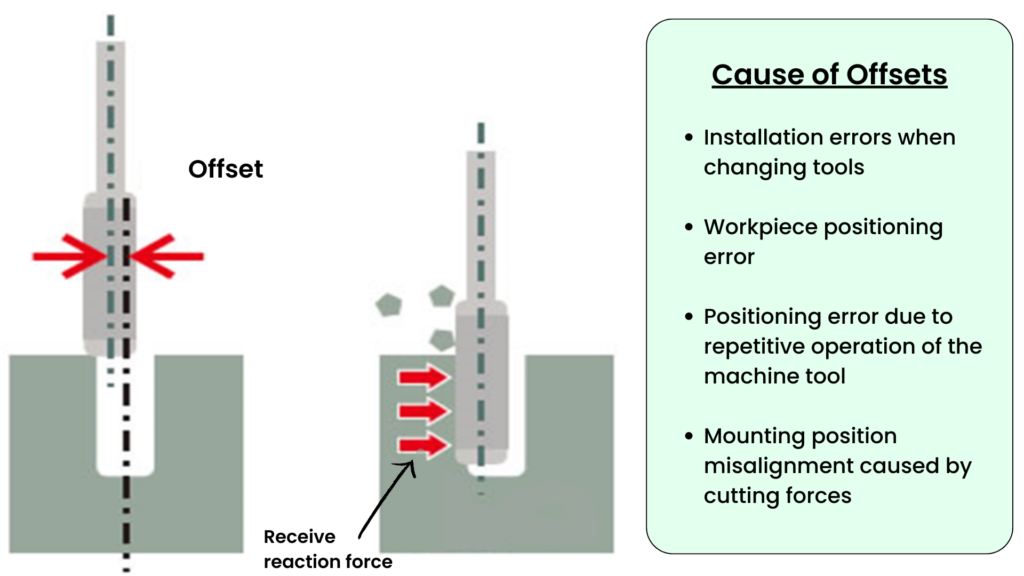

Offsets that worsen machining accuracy.

In hole drilling, there is always a misalignment between the tool center and the pilot hole center.

Depending on the degree of misalignment, the machining accuracy, such as surface roughness and roundness, may deteriorate.

Moreover, as the tool is pushed forcefully into the pilot hole’s deviated position, it also experiences a load due to the reaction force from the pilot hole.

This misalignment not only degrades the machining accuracy but also results in quality variations.

Offset correction with floating mechanism

Takezawa Seiki has developed a floating honing holder that is capable of compensating for minor deviations between the pilot hole and the tool center.

It can respond effectively to even the smallest offsets and accurately follow the pilot hole.

The honing process, which always follows the pilot hole, enhances machining accuracy, reduces quality variation, and prolongs tool life by avoiding excessive force application to the tool.

Furthermore, the characteristics of only Takezawa Seiki

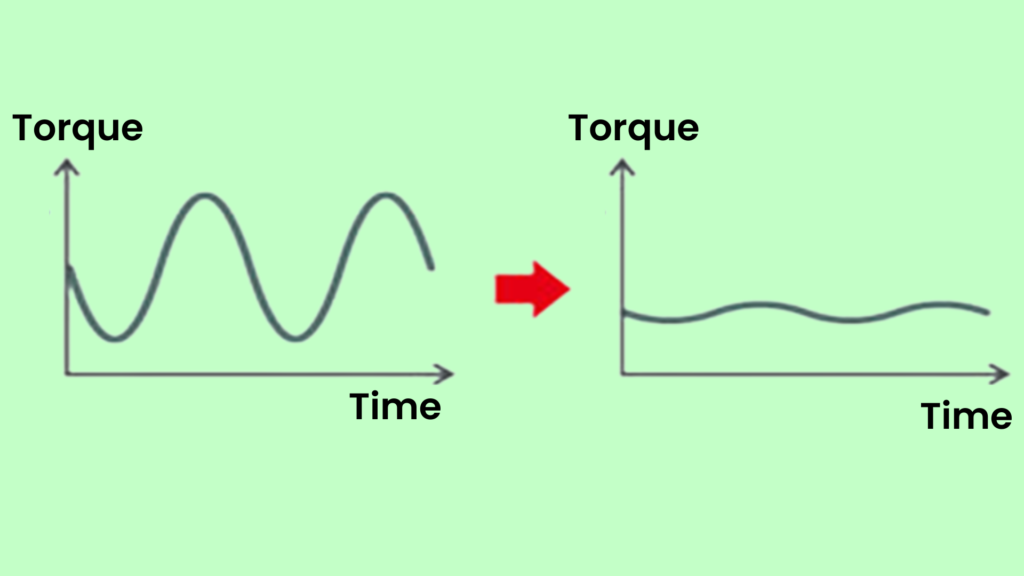

Takezawa Seiki’s floating holder maintains a constant transmission torque, unlike conventional floating holders whose transmission torque is prone to fluctuations. Such fluctuations can result in variations in quality and load on the tool.

While floating honing holders can compensate for offset-related problems, they themselves can cause other issues. However, Takezawa Seiki’s floating holder has a unique mechanism that enables it to maintain a constant transmission torque. This innovation corrects the offset between the pilot hole and the center of the tool while minimizing fluctuations in transmission torque.

Overall, Takezawa Seiki’s floating holder is a remarkable product that takes honing to the next level.

Instead of replacing your machine tool, this alone can improve accuracy, quality, and cost.

Takezawa Seiki’s floating honing holders enhance machining accuracy, quality, and production efficiency while reducing costs. Unlike conventional floating holders, the floating mechanism of Takezawa Seiki’s product accommodates slight unevenness in the positioning between the tool and workpiece, preventing uneven force on the tool.

By improving machining accuracy, quality, and cost-effectiveness without requiring customers to invest in expensive machine tool replacements, Takezawa Seiki’s floating honing holders offer significant benefits to the production line and the economy as a whole.

If you are hesitant about trying the honing process, We encourage you to give it a try at least once. You may find that it is not as difficult or intimidating as you thought.